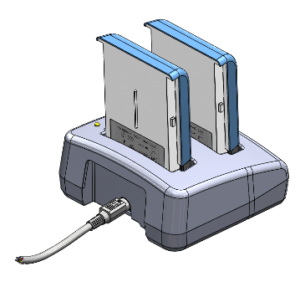

Transceiver & Battery Charger

This project, which had four parts (transceiver, batteries, battery charger, and dongle) presented a number of engineering challenges and design requirements:

- Must be easy to remove and replace the battery, as this process takes place twice a day.

- Must be splash-proof, since the battery charger, transceiver and dongle are all sterilized with a liquid spray. This requirement was particularly challenging for the adjustable knob on the dongle.

- Dongle must work with a pre-selected connector. Two circuit boards and an associated tiny micro-switch had to be packed into the dongle, and then the design had to ensure that the dongle would be mounted correctly on the connector so that the circuit boards and micro-switch would function as desired.

- Must minimize tooling costs. Miro had to design a complex case for the battery charger that could be made economically via injection molding.

Miro successfully addressed all of these requirements, and then went even further to improve the functionality of the four devices. For example, Miro’s unique design for the charger enables the device to be cooled using natural air flow. To improve the functionality of the dongle, Miro designed the knob so that the knob itself, rather than a tiny micro-switch associated with the circuit boards, acts as the stop when the knob is turned.